Project Overview

The Challenge

Between 2011 and 2017, 8.2 million trees were cut down for charcoal production, contributing to 25-35% of greenhouse gas emissions from biomass burning. Existing briquette machines are industrially expensive and inaccessible to communities. There's an urgent need for low-cost, sustainable fuel alternatives.

The Solution

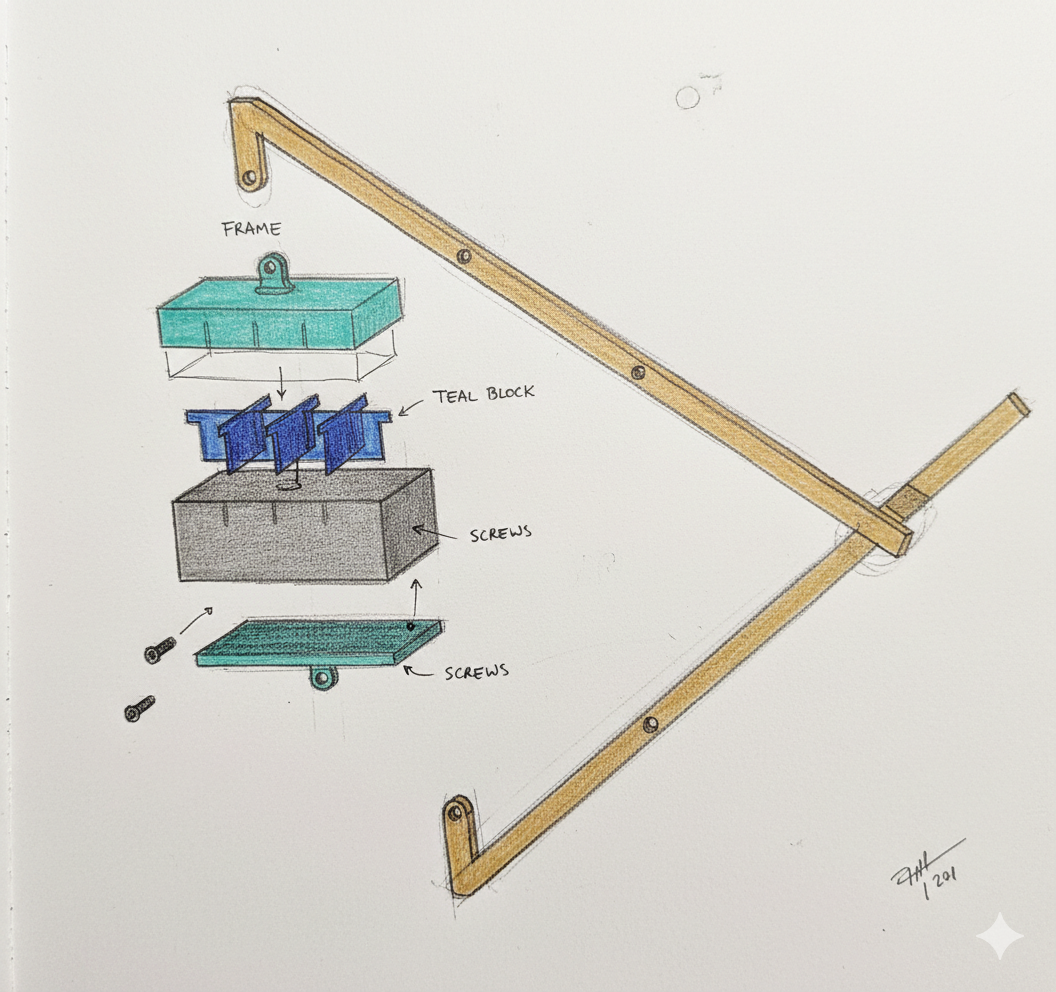

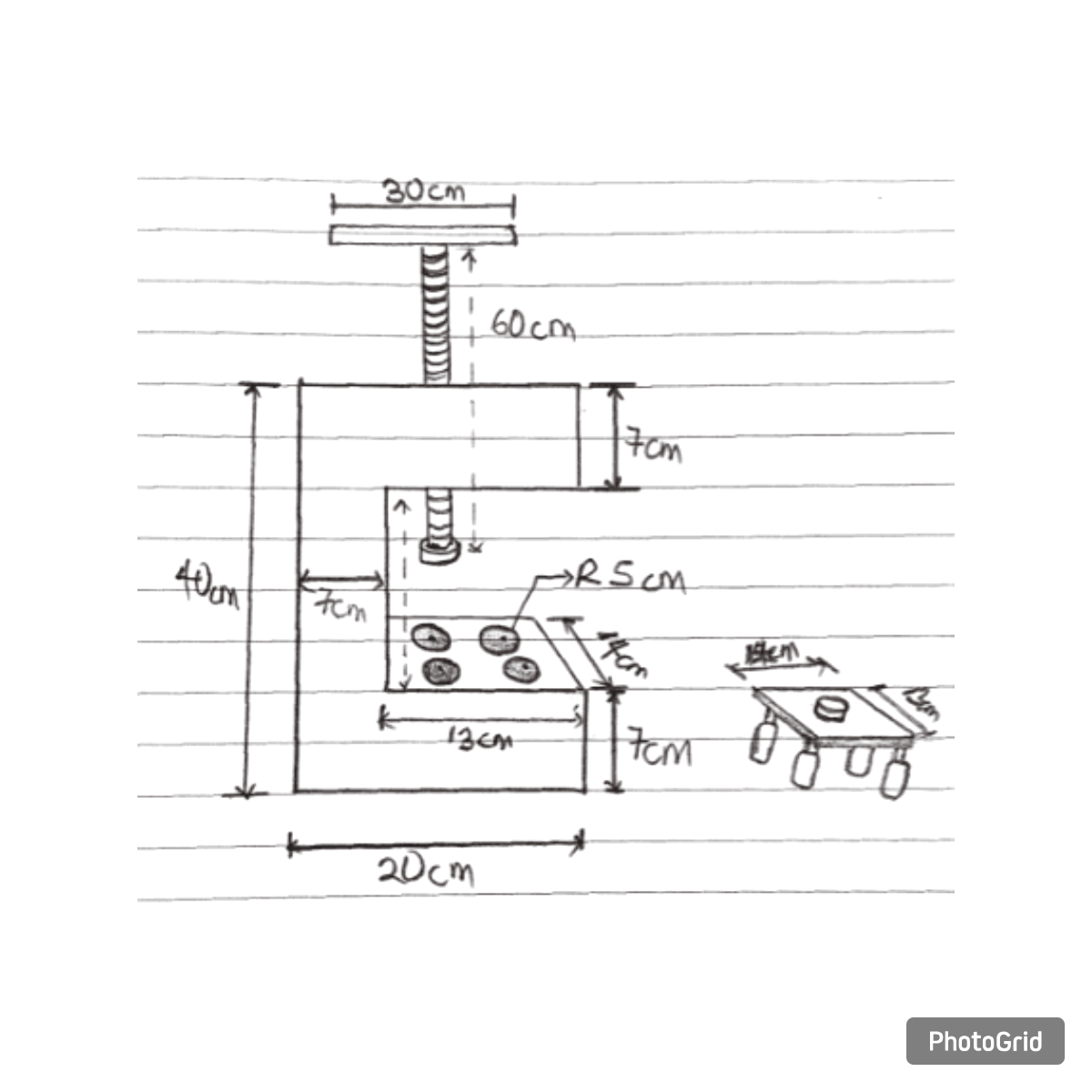

Design a low-cost briquette making machine that transforms organic waste like fruit peels and secondhand clothing into sustainable fuel. This accessible technology provides communities with an affordable charcoal alternative, directly addressing deforestation while reducing greenhouse gas emissions.